Pumps

SCI offers fixed and variable displacement pumps – vane, piston, gear type, and air-driven liquid pump products.

Hydraulic piston Pump

See our Piston Pump Offerings including the following:

-

Nachi PVS, PZS piston pumps. Nachi UGE series unipump pump/motor

-

Duplomatic axial piston pumps including VPPM, VPPL and HPR series

Hydraulic Vane Pump

See Nachi and Duplomatic offerings

-

Nachi VDS, VDR, VDC and UVN series

-

Duplomatic DFP, FV6, FV7, RV1D, RV1P and PVE series

Industrial Gear Pump

SCI provides gear pumps from

-

Marzocchi ALP and GHP pumps in stock. 1P, ALM, GHM and tandem pumps available on request.

-

Duplomatic GP 1P and IGP series and Nachi NASGP/ IPH series now available

For more Gear pump information see link:

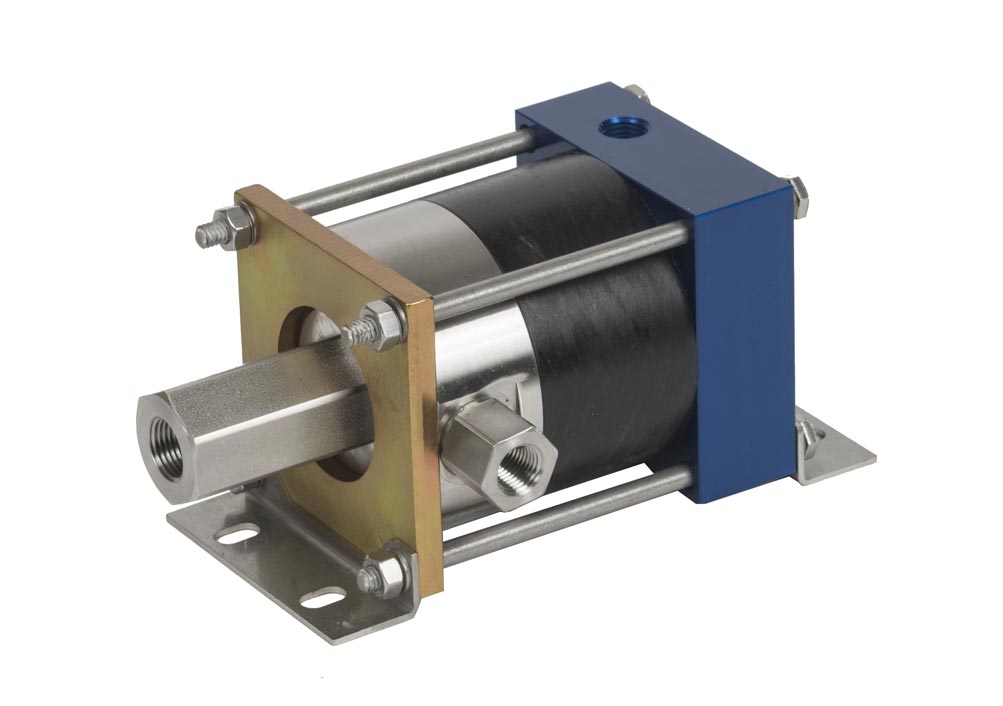

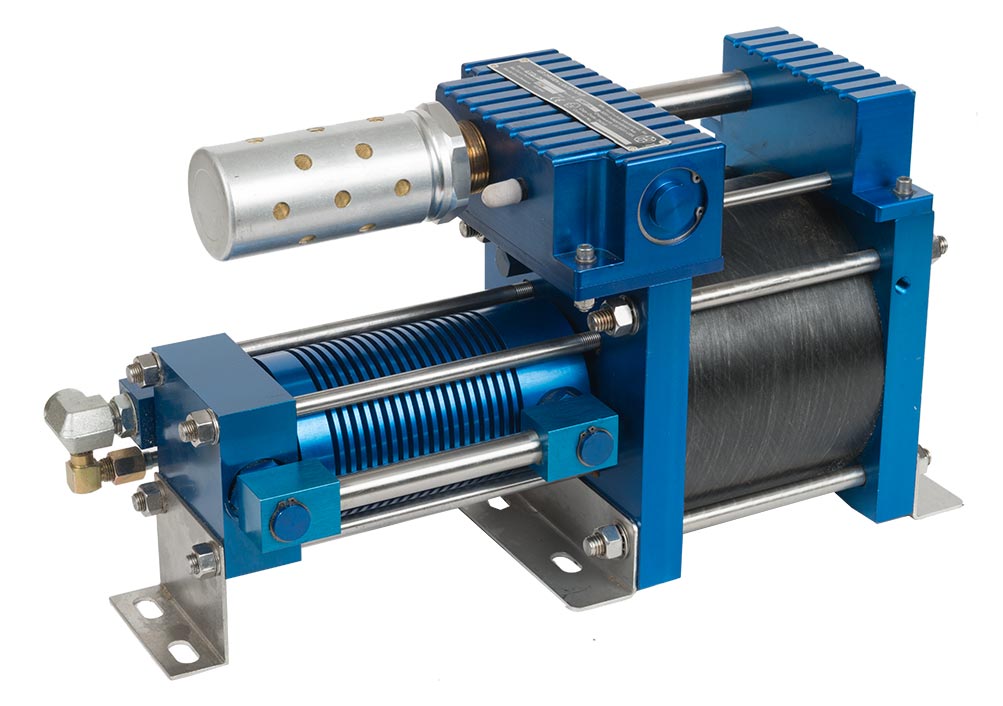

Air Driven Liquid pump

SCI provides top quality air driven liquid pumps from Hydraulics international. Please see link below for detailed information.

Air Amplifier/Gas booster pumps/Intensifiers

SCI has outstanding manufacturers for air amplifiers, gas boosters and Intensifiers.

-

Hydraulics International, Nopak, and Milwaukee Cylinder can meet and exceed your requirements. Contact SCI today for an estimate

For more Air Driven Liquid pump and Gas Booster information see link below:

SCI represents the following brands